Impeller innovation and consideration

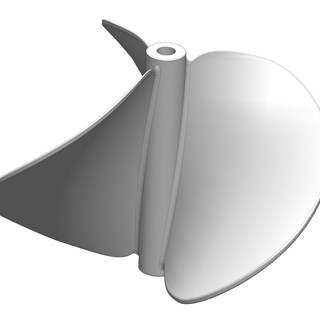

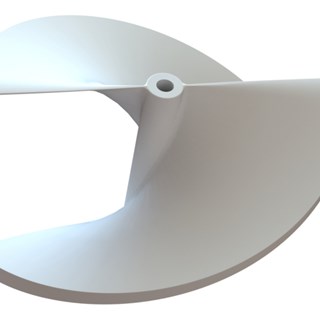

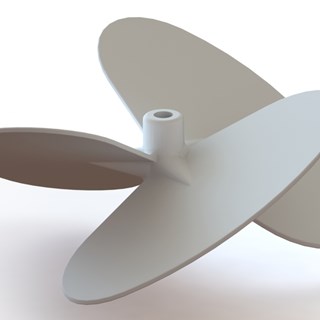

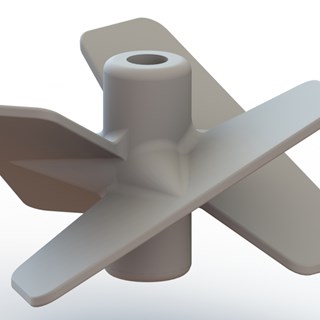

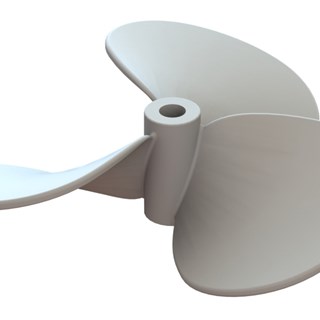

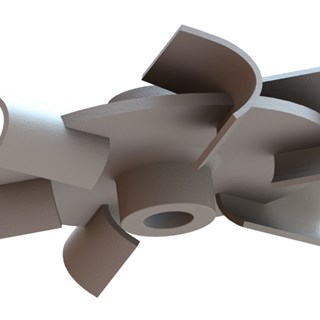

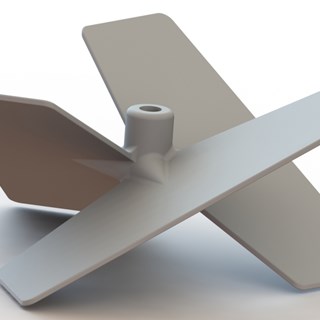

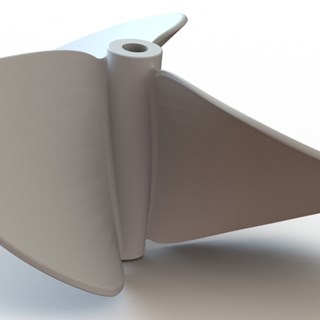

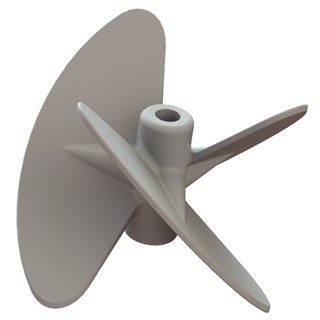

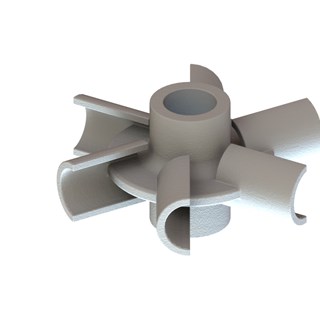

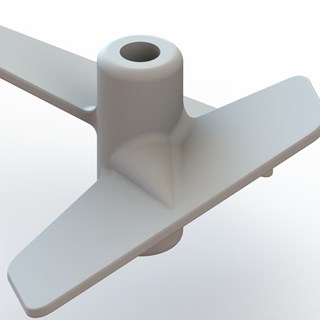

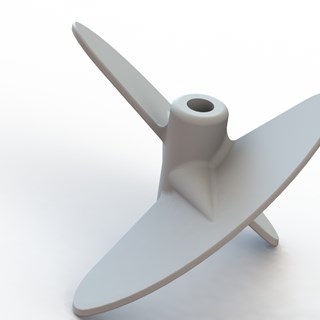

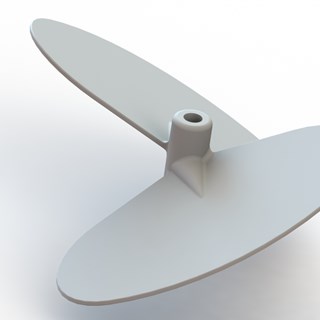

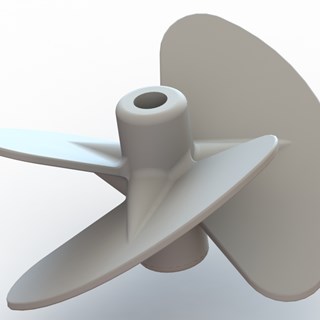

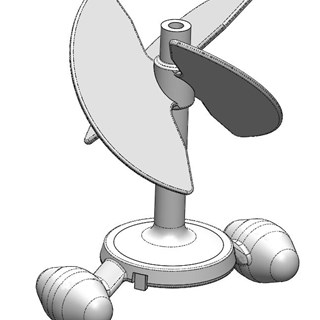

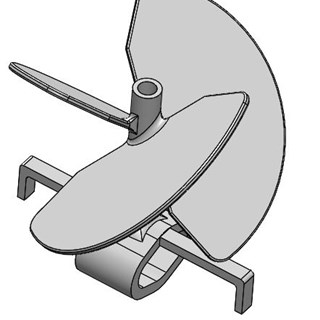

Impellers are axial fluid directing rotating elements for delivering or absorbing energy. These elements with in general few and large helicoidal shaped blades give very high degree of swirling in a vessel or tube. The flow pattern generated in the fluid resembles helix. Impeller dynamics can be modelled by both Bernoulli's principle and Newton's third law. The impeller (propell) is sometimes colloquially known as a screw or a rotor.

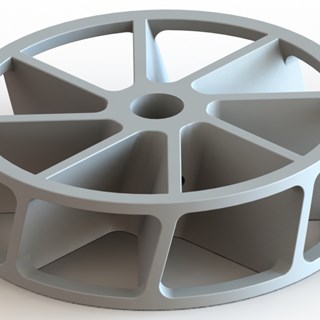

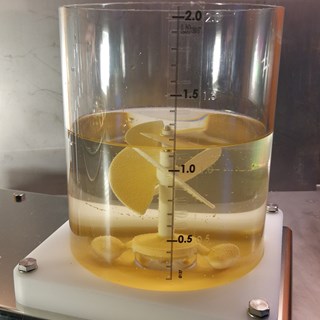

Rotating impellers in agitated vessel's are used to mix fluids and/or hold particles suspended in the vessel. Mostly to combine materials with different properties in the form of solids, liquids and gas. Mixing fluids and particles properly in a vessel or container is very important in order to reduce gradients such as temperature or concentration.

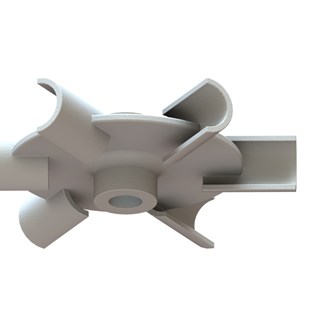

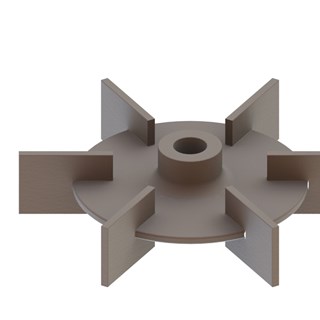

Axial flow impellers impose essentially shear stress to the fluid, and are used, for example, to mix immiscible liquids or in general when there is a deformable interface to break. Another application of axial flow impellers are the mixing of very viscous fluids.

Axial flow impellers impose essentially bulk motion, and are used on homogenization processes, in which increased fluid volumetric flow rate is important.

- Shear stress may be rough to mammalian cell and of no importance to bacteria

- Tip-speed cause shear stress and impeller design may reduce tip-speed with constant capacity

- Cavitation can occur in many ways on an impeller surface. The two most common types of propeller cavitation are suction side surface cavitation and tip vortex cavitation.