For CellVessel bioreactor's a fair range of sparger's should satisfy any needs

A - Select from Configurator Tool (section 5) a tubular sparger mounted horizontal under impeller or straight down vertical oriented sparger - both design equipped with E-beam tolerant PolyCarbonate (PC) closed tube with drilled holes.

- Macro-porous closed PC tube with typical 12 drilled holes 500 µm size (different size holes, numbers, orientation on demand)

B - Select from Configurator Tool (section 5) good performaning spargers mounted horizontal under impeller or straight down vertical oriented sparger - with E-beam tolerant glass frits for low contact angle:

| Designation according to ISO 4793-80 | Pore size in µm | Availability |

| P 500 | 250 - 500 | in stock |

| P 250 | 160 - 250 | in stock |

| P 160 | 100 - 160 | in stock |

| P 100 | 40 - 100 | in stock |

| P 40 | 16 - 40 | in stock |

| P 16 | 10 - 16 | in stock |

| P 1.6 | 1 - 1.6 | in stock |

MAX sparging system gas pressure 500 mBar

Examples of various size PE micro and macro-porous bodies. Drilled holes on horizontal sparger bodies. Micro-porous glass bodies with 50 µm pores.

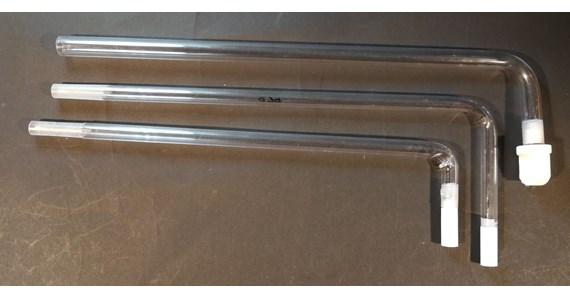

Examples of various super macro ring Nylon spargers with drilled holes designed arranged under impeller or turbine. Horizontal arranged Micro porous bodies with 10 µm pores. Any number of drilled super macro holes in horizontal transparent L-sparger made from PC. Check out further information Scientific Work.

Its important to pay attention to the "contact angle" of the sparger materials chosen. Non-surface treated PE is above and stainless steel metal and glass is below 90°. Take a look at our Glossary.