CellTumbler system parts

CellTumbler is based on a range of components easy to replace and assemble onto the T-frame.

Brushless 10 watt DC motor with ball bearings, planetary gearbox with ball bearing, support housing with ball bearing for vastly extended service life. Micro processor controlled motor speed with feed-back for high accuracy and potentiometer adjustment of stroke number ranging from 0 to 40 strokes per minute. Stroke width adjustable between 35, 40, 45, 50 mm corresponding 5, 6, 7, 8 degree rocking angle.

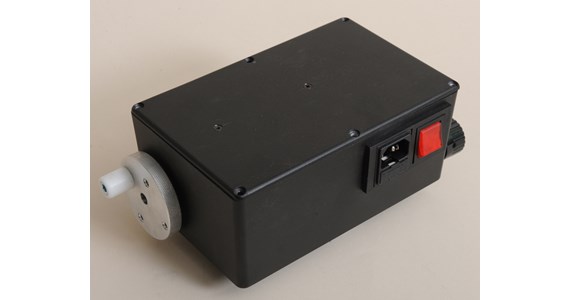

Power connection from 230 VAC only with standard IEC power cable to IEC C14 inlet socket into 0,5 amp fused and switched IEC Power Inlet Module in IP54 rated and coated aluminium enclosure with dimension 186 x 118 x 80 mm.

Heating-Control-Unit from front

Standard Heating-Control-Unit front

Heating-Control-Unit rear

Heat-Control-Unit includes 2 parallel and identical regulating channels in the same box. Sensor input for each of the two channel is Pt-100. Temperature regulator with PI algorithm action and numerous user adjustable features. This unit for individual heating element control on one or two platforms. Connection to 230 VAC only, with standard IEC power cables to C14 inlet socket (2 amp fused) and switched IEC Power Inlet Module in IP54 rated and coated aluminium enclosure with dimension 186 x 119 x 79 mm.

Heat-Control-Unit facilitates for each channel:

- One Pt100 sensor input

- One 230 VAC outlet rated at 230 watt for platform heating

- One 18 VAC constant power outlet for one 3 Watt sterile filter heating

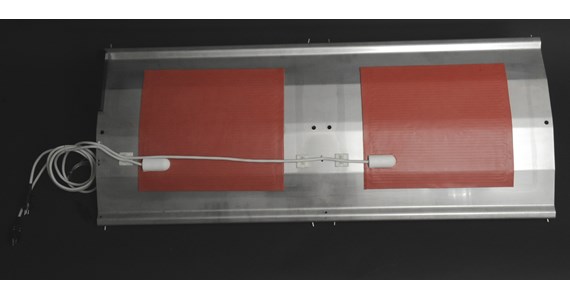

Stainless steel sheet bended to allow accommodation for the culture bag(s) curvature. Platform comes with 200 Watt heating element for use on either side of the platform (2 elements for the dual and 10/20 platforms) and a hanger kit to support the sterile filters suspended to reduce media damage.

Gas-Units designed for 2-6 bar gas inlet pressure to be regulated down to 1 bar by the pressure regulator. Further connection for in/outlet selectable with standard fittings for G1/8” thread.

Choose 2 of Gas-Units from:

- One 150 mm long precision rotameter 0-50 ccm Air or CO2 assembled with one inlet pressure control.

- One 150 mm long precision rotameter 0-150 ccm Air or CO2 assembled with one inlet pressure control.

- One 150 mm long precision rotameter 0-300 ccm Air or CO2 assembled with one inlet pressure control.