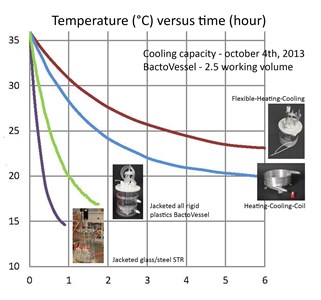

How much energy can a liquid jacked remove

For water conveying Process-Control-System (PCS) CerCell has tested 4 different configurations simulating an exothermic reaction taking place inside the fermenter. A heating element arranged inside the liquid was set at the mentioned temperatures and temperature versus time drop measured. General cooling water flow 2 liter/min, 12°C inlet cooling water, 500 rpm turbine speed in SUF.

- FHC – Flexible-Heating-Cooling element wrapped around the SUF with 5.5 liter VV, 2,5 liter WV, removed power ~5 watt / liter media

- Aluminium RHS coil encapsulating the SUF with 5.5 liter VV, 2.5 liter WV, removed power ~10 watt / liter media

- Integrated Single-Use-Jacket on SUF with 5.5 liter VV, 2,5 liter WV, removed power ~20 watt / liter media

- Integrated jacket on UniVessel STR - glass/steel, removed power ~25 watt / liter media

In practice we have seen that a 5.7 liter BactoVessel mounted in the RUJ, connected to a Biostat PCS further connected to 15°C external cooling water supply are able to hold the SUF at 37°C even if 300 watt is lost continuously in the 4 liter WV broth.

Find article here about "Thermal transfer on 13 liter SUM"