Developed in collaboration with MSD

3.2 liter Single-Use-Bioreactor (SUB) developed in collaboration with the BioProcess Development Group at Merck & Co., Inc., 2000 Galloping Hill Road, Kenilworth, NJ 07033 U.S.A. (known as MSD outside the US and Canada).

Features:

- All rigid mono component plastics

- Magnetic-Bottom-Drive (MBD)

- 3 free sensor ports PG 13,5

- 1 sensor ports PG 13.5 installed with PolarWell for non-invasive inserts for polarographic DO sensor

- 1 sensor ports PG 13.5 for optional all polymeric pH Single-Use-Sensor with K9 connector

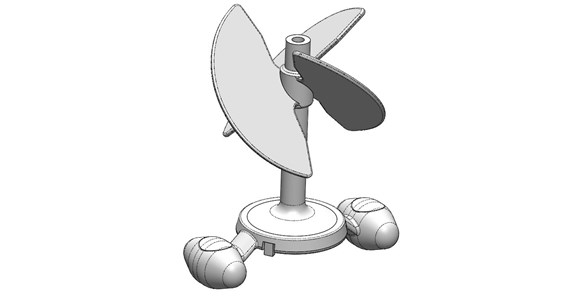

- Special designed impeller – integrated with magnet motor named Aero

- L-sparger with 7 x 0.5 mm drilled holes (max sparge gas pressure 500 mBar)

- 3 x 10 mm baffles extending from head plate

- 2 x deep tubes with CPC connector for ATF-2 connection

- 12 small diameter hoses for various inlet and outlet length 600 mm

- SUB outside dimension OD 137 x H 270 mm = 3.2 liter Vessel Volume (VV)

- Working Volume (WV): 300 ml required to cover the ceramics bearing, 500 ml will cover sensors, 1,000 ml will fully cover the impeller

Need to have accessories:

- Re-usable Stainless Steel gas cooler with OD 12 mm inlet and 6 mm outlet

- One of 3 different size Magnetic-Stirrer-Table (MST)

- If needed - converter kit for servo motor

Parts manufactured and supplied by CerCell seen from left: one gas cooler in place, many customized gas coolers, MST-U-Compact occupying less space on lab table.

Nice to have accessories

- Re-Usable-Jacket for liquid heating/cooling fitted to MST (RUJ-MST)

- Electrical-Heating-Blanket 110 or 230 VAC

- Sterile-Filter-Heater 110-230 VAC

- SUB-Support-Square (SSS) plate for any of the 3 MST

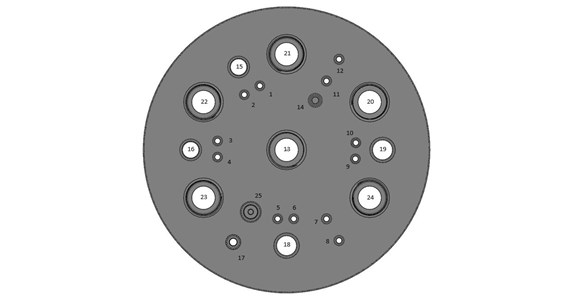

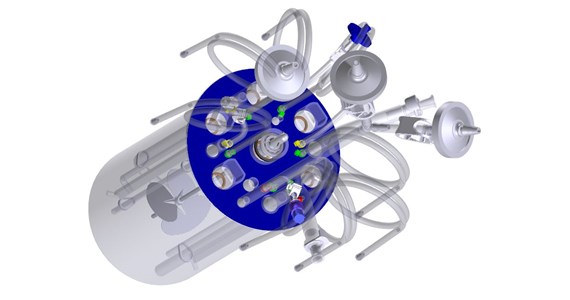

Seen from left: Packed head plate layout. The final SUB design rendered. At right the highly efficient Aero magnet motor with ceramic bearing and impeller.

Baffles:

- Three wall baffles of width 10 mm x thickness of 4 mm.

- Extend from head plate down to 0,5 L, 43 mm from the bottom.

- Approximate clearance between SUB wall and baffle is 4,5 mm.

Agitation:

- Aero MBD/ elephant ear impeller, OD 60 mm, 3 blades, 45 degrees clock wise rotation and down flow

- Power Number 2.4

- Impeller mounted 55 mm from the bottom

- Extensive fluid dynamic analysis performed for minimum shear forces and gradients

Check out variants and a few standard products under Commerce